Industrial Internet of Things Provides Fabricators with a Data-Driven Advantage

WeldCloud safety stores data on your company’s intranet, where it is password protected.

- Enable bi-directional communication to pull in welding procedures and schedules, verify operator qualifications and confirm machine setup.

- Develop schedules on a single machine, move them into the cloud and then push them out to other systems, whether that’s one machine, a group of machines or groups of machines in multiple locations.

- Remotely manage parameters, set limits and set alarms for deviations.

- Facilitate traceability from single welds to the complete product because the core of a data-gathering system provides a comprehensive database containing key information of every seam. Automated documentation of every step in the process chain (e.g., filler metals, consumables, operator qualifications and welding parameters) is becoming essential for structural steel construction, ship, offshore, pressure vessel, military, automotive, crane and fabrication in many other industries.

- Job status and real-time response to production situations – such as alerts when consumable levels run low, generation of a predictive maintenance schedule or pushing out a re-stocking text to suppliers.

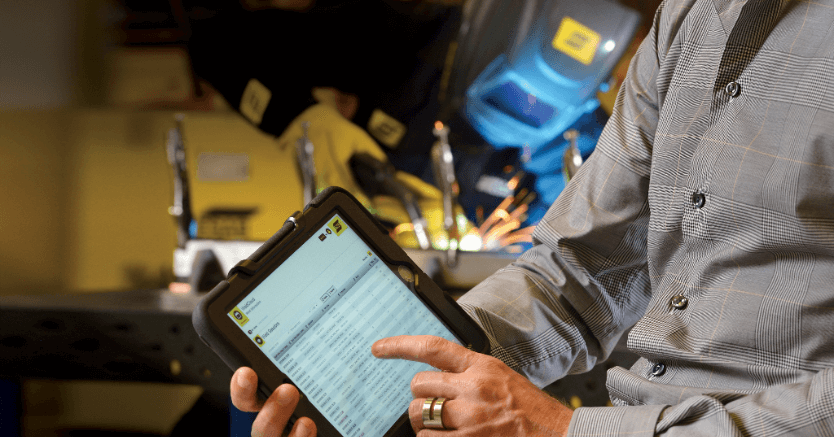

- Share and analyze data by teams across multiple data collection sites, using any computer, tablet or smart phone connected to the same internal network as the welding systems and database.

- Remote connection to experts for process optimization, updates and troubleshooting.

- Web-based reporting provides up-to-the-second status information, highlighting production and quality concerns to increase overall quality and production performance.

- Integrate with ERP systems like Oracle®, SAP®, IBM and SharePoint, plus analytics and reporting tools such as ClickView, Qlik®, SAS® and Tableau®.

WeldCloud enables managers in a central location to monitor the status of equipment from multiple facilities.