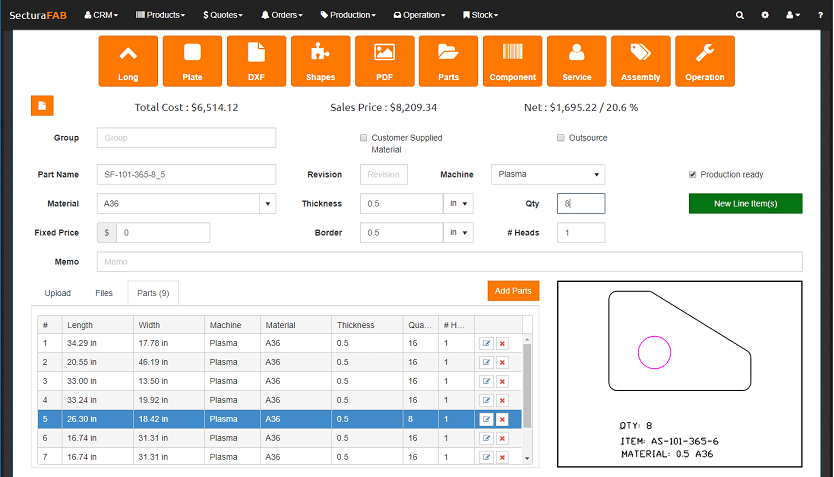

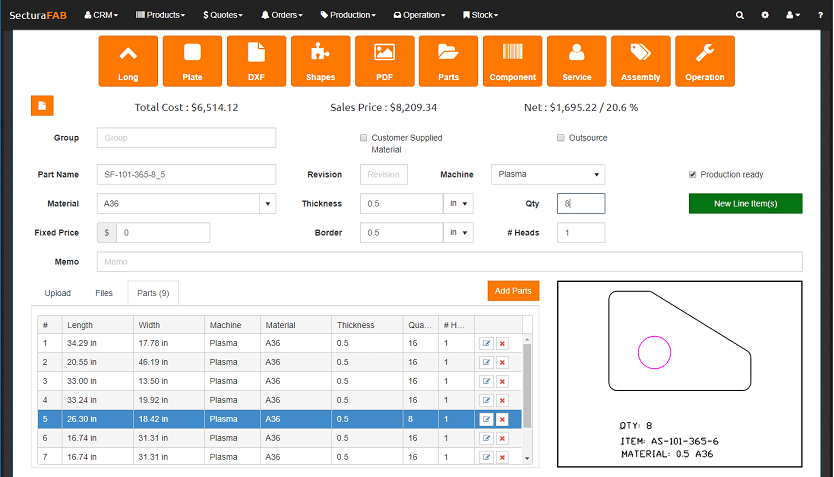

Geometry-Based Quoting

Today’s automated quoting software is driven by part geometry improving quote speed and accuracy.

Integrating secondary operations into the quote captures all aspects of the job completely and accurately.

- Accessible: From laptops to tablets and cellphones, quotes can be generated on any device.

- Simplified: Dashboards may contain fields that launch behind the scene calculations (rates, material costs, machine run-time, secondary operations needed and associated costs, etc.).

- Fast & Accurate: Eliminating the need to transfer values between systems eliminates errors while simplifying and speeding the process.

- Consistency: Customized forms provide a common template ensuring that all quotes are consistent and profitable.

- Affordability: Updates are performed at a single location rather than multiple sources. Cloud-based quoting is often available as an affordable subscription service.