Introducing the iTool© Shelf Visual Press Brake Tooling Storage System

Manufacturers Get LEAN with Versatility Professional Tool Storage Products

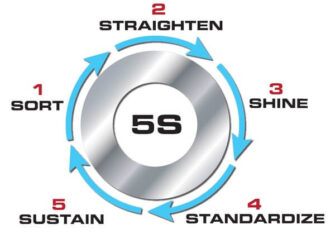

The iTool Shelf is Versatility’s latest addition to a product line which has proven instrumental to implementing Lean and 5S initiatives in sheet metal manufacturing operations. Designed to improve the fabricators’ safety, productivity, lean and 5S programs, iTool Shelf offers 500 pound capacity sliding tool shelves which are configurable for any style of press brake tooling. At full extension the shelves lockout, allowing ergonomically safe lifting. The lockout feature further enhances safety by preventing shelf movement when removing or returning tools to the unit. The iTool Shelf design supports Lean’s Visual Factory concepts by allowing tool type and location to be viewed from all sides of the unit. With up to 8 sliding tool shelves per unit, the iTool Shelf creates a high density storage solution which saves valuable floor space compared to traditional tool cabinets.

Versatility’s patented shelving units, workstations, modular cabinets, and change-over carts allow manufacturers to:

- Work Safer by utilizing Versatility’s ergonomically designed drawers, shelves, work surfaces and unique 1-aTa-Time® drawer interlock system;

- Increase Efficiency and Green Light Machine Time through reducing wasted motion during change-overs;

- Protect Valuable Tooling with Versatility’s specially designed divider systems;

- Improve Organization and Save Time Searching by assigning inventory to unique identifiable locations;

- Maximize Floor Space with Versatility’s high density storage solutions.

New to Lean Manufacturing and wondering what it all means? A simple search will reveal that there are many different definitions and interpretations. This is due to the fact that Lean has been a continuously developing philosophy whose application is unique in each organization. Originally created as part of an MIT study in 1990 and first implemented by Toyota as the Toyota Production System (TPS), Lean Manufacturing is not a new concept. Lean has had many names over the years: World-Class Manufacturing, Continuous Flow Manufacturing, Lean Sigma, and Agile Manufacturing are just a few. Each of these concepts are slightly different, yet at the core they strive for the same goal: to eliminate “Muda” or waste from an organization. Perhaps the broadest definition is the best. Lean Manufacturing can be described as the set of tools that assist in the identification and elimination of waste. By focusing on reducing waste, organizations are able to increase quality, productivity, profitability, and customer satisfaction.

Versatility Professional Tool Storage products are designed to help implement many aspects of Lean including: 5S, Single Minute Exchange of Dies (SMED), Continuous Flow, and Overall Equipment Effectiveness. Our products are equally effective at helping manufacturers who are just looking to improve safe handling of tools, increase shop floor organization, or streamline change-overs without a formal Lean program. Partner with Versatility to get your safety, organization, or Lean Manufacturing initiative on track.

For more information and to see how Versatility’s products can positively impact your manufacturing operation, call 1-866-382-0482, visit www.professionaltoolstorage.com, or stop by Booth A5067, Nov 6 -9, 2017, FABTECH 2017, McCormick Place, Chicago, Il.