Weld Inspection for Tube Fabricators in the Automotive Industry

The challenge of meeting strict standards while avoiding mismatch, errors in the scarfing process, and hairlike scratches

By Cornelius Sawatzky, sales manager, North American tube and pipe weld inspection systems, Xiris Automation Inc., Burlington, Ontario, Canada

Tube fabricators that supply the automotive industry are required to meet strict standards that are consistently becoming more stringent and difficult to meet. One of the standards that has presented challenges for tube fabricators is reducing the weight of components to meet weight limitations. The strict weight limitations are a result of the push toward fuel-efficient vehicles. Suppliers of automotive parts are constantly asked to shave off fractions of ounces in each of their components to create lighter cars that will use less fuel.

For tube fabricators to meet the imposed weight limitations, they must use lighter materials, thinner wall thicknesses, and higher yield strength materials. At the same time, they must still meet strict high-quality standards while dealing with the added challenges from the lighter and higher yield strength materials and thinner wall thicknesses that make tubes more susceptible to various defects. These defects can include mismatch, errors in the scarfing process, and hairlike scratches on coated tubing.

Mismatch

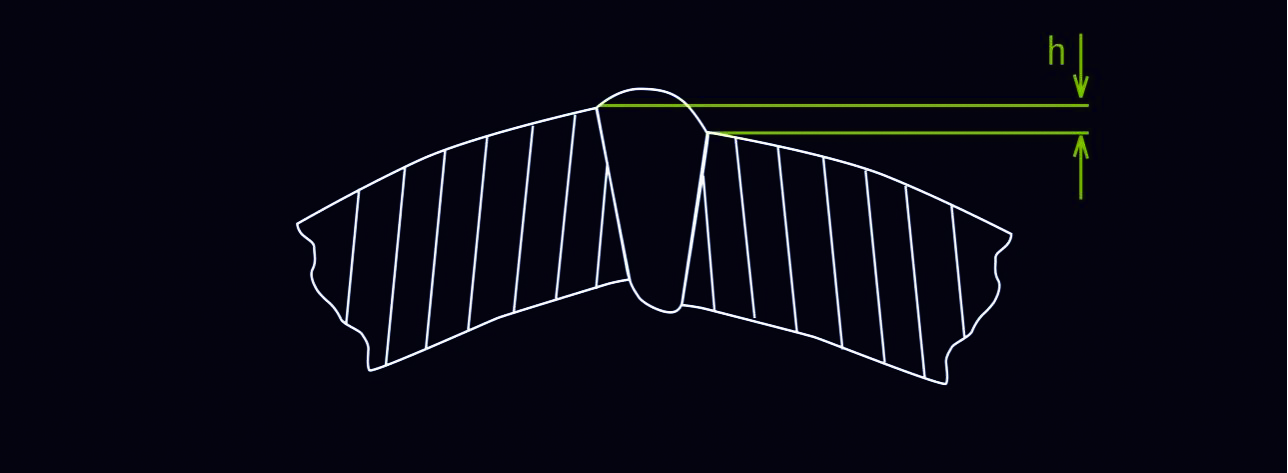

Tubes fabricated from a higher yield strength material are especially susceptible to mismatch. This is a defect caused by the uneven joining of two edges of the tube material strip prior to welding. Following the welding of the tube, typically a grinding or scarfing process will be employed to remove any excess bead that is out of round. If there is any mismatch on the tube, part of the wall on the higher side of the mismatch may be removed during the grinding or scarfing process, resulting in significant thinning of the tube wall. Hence, monitoring for mismatch is vital, even more so when dealing with thin-walled tubes.

Traditionally, tube fabricators will follow a widespread practice of allowing mismatch on a longitudinal welded tube of up to 5% of the wall thickness. When dealing with a thinner wall thickness, this 5% tolerance becomes much smaller. Additionally, when dealing with higher yield strength materials, the material is especially susceptible to mismatch, and the rate of failure becomes quite high with the allowed 5% tolerance. As a result, most tube fabricators looking to meet weight requirements will reduce their mismatch tolerance to the 2–3% range, creating little tolerance for mismatch on the tubes and greater difficulty in being able to see and detect the mismatch.

Errors in the Scarfing Process

Aside from mismatch and the resulting defect it can cause during the grinding or scarfing process, tube fabricators must monitor the scarfing process itself for errors such as insufficient or excessive scarfing. The tubing used for automotive applications must be perfectly round to create a good seal when compression fittings are applied. This means the tube surface must be free from any weld beads that are to be removed in the scarfing process. The scarfing process can be performed in several ways, such as cutting off the weld bead with a knife. Unfortunately, scarfing can often be the primary reason for a leak on a compression fitting.

Insufficient scarfing of the welded tube can mean a small portion of the weld bead is left protruding from the surface of the tube. Comparatively, excessive scarfing can often be more challenging to detect because the tube may appear perfectly round to the human eye while a nonuniform wall thickness is lurking below the surface. This can result in a thinned portion of the tubing wall that may, as a result, compromise the integrity of the tube.

Hairlike Scratches on Coated Tubing

Within several industries, including automotive, key applications will utilize coated precision tubing. This is because the protective tube coatings provide additional abrasion and corrosion protection for the tubing in the field. However, these plastic protective coatings can often present a challenge that results in surface imperfections or variations. The protective coatings are typically extruded onto the welded tube as part of the last step in the process. With time, the extrusion dies that are used to create the desired profile can wear out or pick up impurities. This means imperfections can appear as hairlike scratches that run the length of the tube.

This becomes an even greater issue when the coated tubes are used in applications such as fuel transport, where they must be coupled to other components using a compression fitting. If any hairlike scratches are on the coated tube when the compression fit is applied, a leak path could result and create hazardous conditions. As such, coated tubes must be thoroughly inspected to ensure they meet the exact requirements and standards of customers in the automotive industry. The manufacturer must monitor the coated tube for the presence of any hairlike scratches greater than 0.015 mm in width or depth, which can be extremely hard to detect. Even once the surface defects are detected, it is often too late to correct the source on a tube production line, and a section of the tube must be scrapped.

Using a Scratch Inspection System

The only way to properly detect surface related issues on a coated tube is to use a laser-based surface inspection system. Using a system such as the WI-2200 – 360° scratch inspection system provides operators with measurements all around the tube so they can detect any of the aforementioned surface variations, including hairlike scratches. This allows operators to take proper action and address the issues before they worsen (or it becomes too late) and the tube is sent off to a customer. As a result, automotive industry standards are met, suppliers and manufacturers will notice improvements in quality, and the number of defective products and waste are reduced.

Fig. 1 — A mismatch defect.