Life Cycle Assessments Provide Environmental Performance Answers

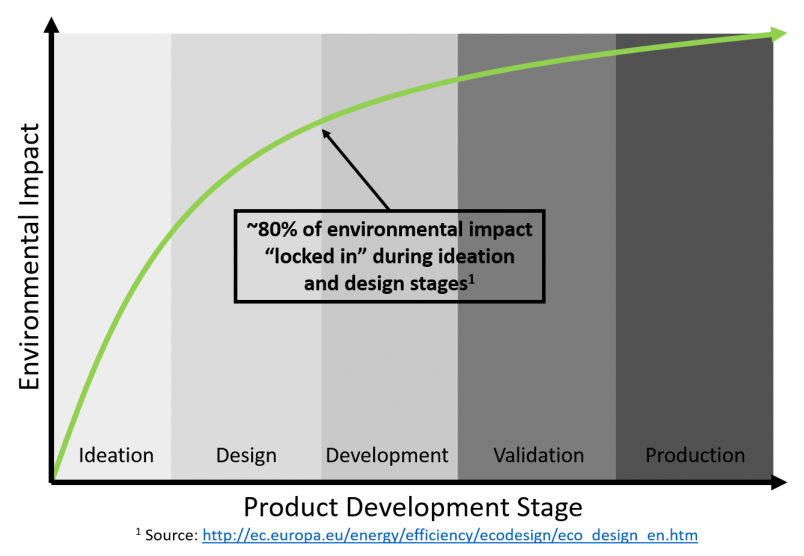

Figure 1: Life Cycle Assessment and Product Development. Source: http://ec.europa.eu/energy/efficiency/ecodesign/eco_design_en.htm

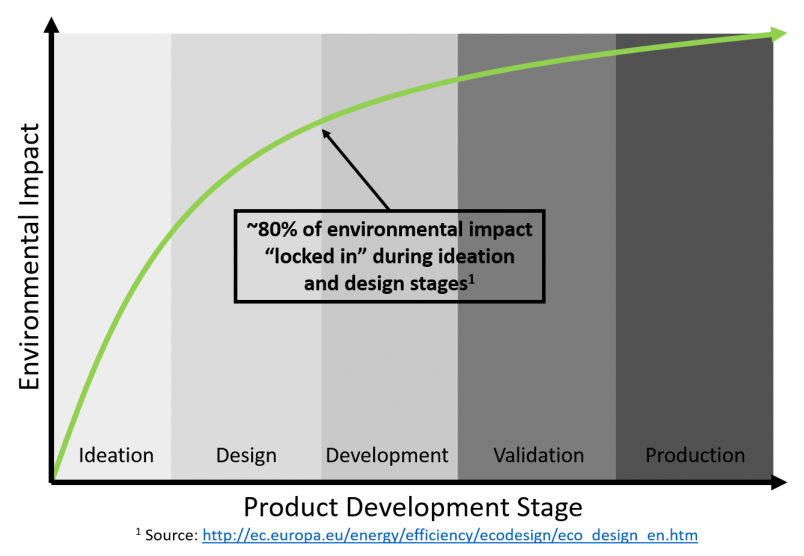

Figure 1: Life Cycle Assessment and Product Development. Source: http://ec.europa.eu/energy/efficiency/ecodesign/eco_design_en.htm