North America's Largest Metal Forming, Fabricating, Welding and Finishing Event

A new pavilion and theater provides opportunities to experience, learn about the fast-growing technology

With interest skyrocketing in one of the industry’s hottest topics, North America’s largest metal forming, fabricating, welding and finishing event has added a new 3D/Additive Manufacturing Pavilion to FABTECH this year, which runs Nov. Read Post

Waterjet Cutting for Fabricators

By: Brian Sherick, Flow International

The manufacturing industry is transforming as companies are consistently pushing boundaries on what we can make and how. The flexibility fabricator’s gain from waterjet cutting has grown the process to become a fundamental part of fabrication shops. Read Post

Visit Komatsu in booth A5231 at FABTECH 2017

Komatsu servo press feature built-in load monitors, on board graphic displays of energy consumed/saved, all slide motion paraments such as pendulum stroke & speed, velocity, dwells, material “touch points” by angle and distance from BDC; automatic settings by part number such as slide adjustment position, cam settings, load monitor limits. Read Post

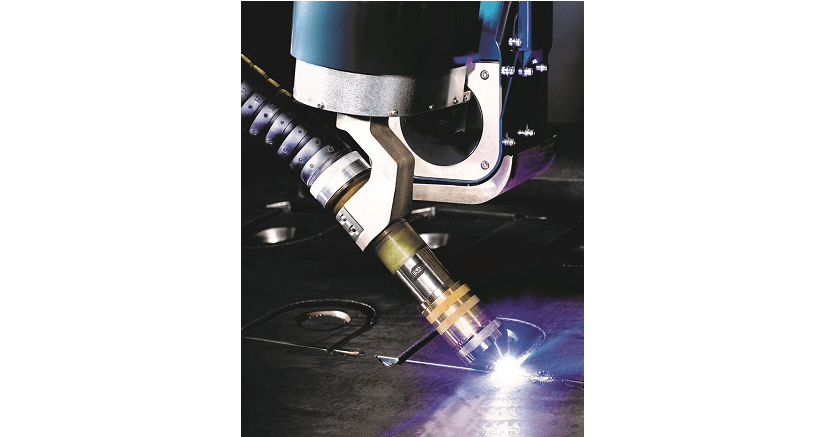

Is plasma a viable alternative to laser?

High definition class plasma along with continued advances in torch and consumable technology is responsible for markedly improving the cut capabilities of plasma over the past two decades and now a new class of plasma, called X-Definition, is further enhancing plasma’s ability to tackle high precision applications. Read Post

New Opening Keynote Format Set for FABTECH 2017 to Motivate, Inspire Attendees

FABx Tech Talks feature messages about transformation, growth and the future of manufacturing FABTECH 2017, North America’s largest metal forming, fabricating, welding and finishing event, is embracing a popular tech talk concept with the addition of short inspirational talks given by industry visionaries on their experiences and thoughts for how innovation is driving manufacturing forward. Read Post5 Sales and Marketing Adjustments Manufacturers Must Make to Reach Millennials

By: Josh Curcio, protocol 80, Inc.

By 2020, 50% of the workforce will be millennials. So what does this mean for you? Read Post

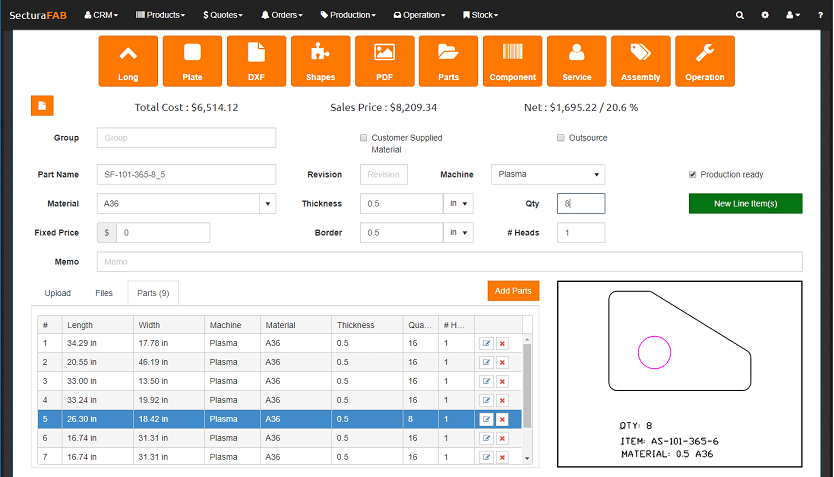

Geometry-Based Quoting

By Brad Stropes, SectruaSOFT

Could your quoting process be costing you money? If you’re still quoting manually, with Excel or even via a traditional MRP system the short answer is “Yes”. Read Post

ORII to showcase Press to Press Transfer and Compact Feed Technology at FABTECH

Orii is the go to company for Press to Press Transfer Systems and Coil Feed Systems for the Japanese Automotive Parts Suppliers. ORII has captured over 50% of the Japanese automotive metal stamping market. Read Post

5 Ways Manufacturers Can Sustain Company Growth

By John Dearing, Managing Director, Capstone Strategic, Inc. Do you want to grow your business? Of course you do. After all, growth is the key to a successful company and, without it, a business is almost certainly declining. Read PostESAB to Demonstrate Next-Generation Plasma Beveling Solution at FABTECH 2017

By Steve Zlotnicki, Global Product Manager, ESAB Cutting Systems

Bevel cutting with plasma has become increasingly common over the last few decades. In the 1990s, only a handful of suppliers had the engineering power and process knowledge required to deliver such a complex system, and prices usually started in the neighborhood of $350K to $500K for a complete machine installation. Read Post